In the fall of 2014 I took ME 240, Mechanical Instrumentation, a course described on the class website as:

This course is designed to provide the students with a background in a broad number of transducers and measurement systems for recording and controlling real world processes and conditions. This course will combine a combination of lecture, laboratory and additional hands on work to teach the indicated topics.

Every student purchased an NI MyDAQ and learned the basics of LabView to create simple DAQ systems. The final project for the course was open-ended and allowed the students to direct the project as long as it fit the guidelines (at least one transducer of our choice, as well as used LabView and measured some sort of signal). My project partner and I decided to instrument a simple lawn mower engine and calculate mass flow as the primary measurement; however, in total we measured six different signals:

- Exhaust Gas Temperature (EGT)

- Wideband O2 (UEGO)

- Throttle Position (TPS)

- Intake Air Temperature (IAT)

- Manifold Absolute Pressure (MAP)

- Crankshaft speed

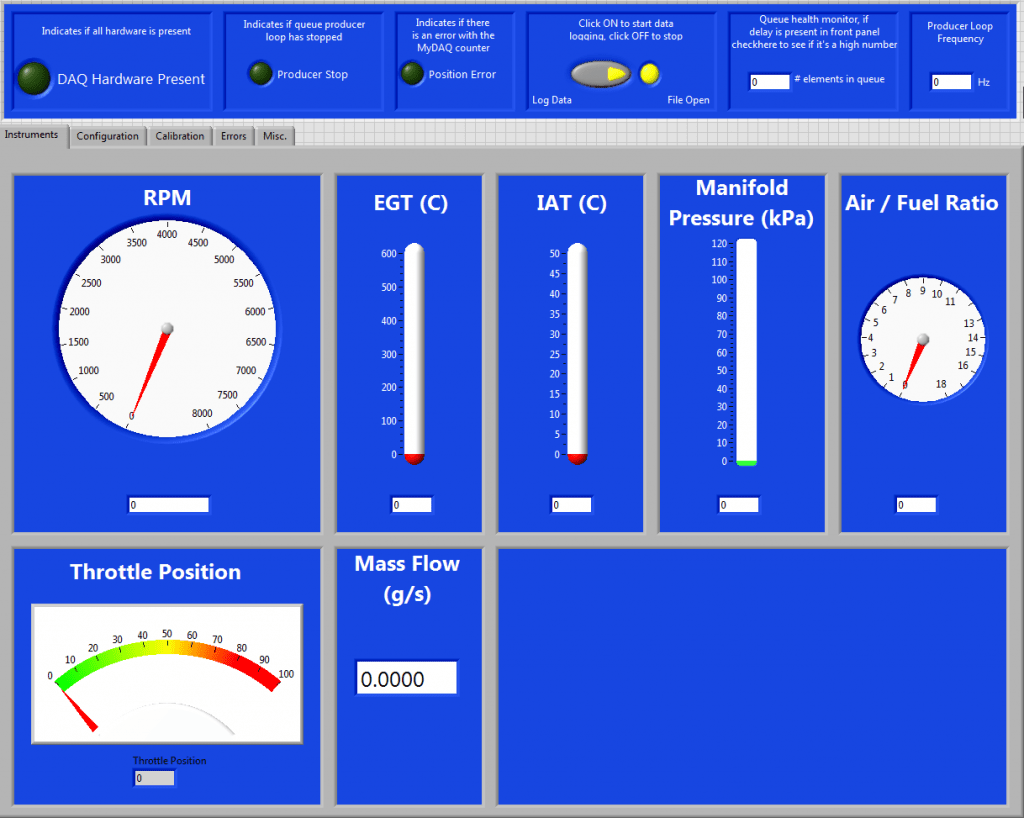

The front panel for our final project, we tried to make the main interface as simple and readable as possible with configuration in other tabs.

We calculated mass flow using the speed-density algorithm, adjusted for air density. We also measured other parameters, such as EGT from cold-start and heat soak after shutdown. Live information was displayed on a front panel and the user had the option to log data, as well as the ability to configure various parameters such as sample rate, transducer configuration, etc.

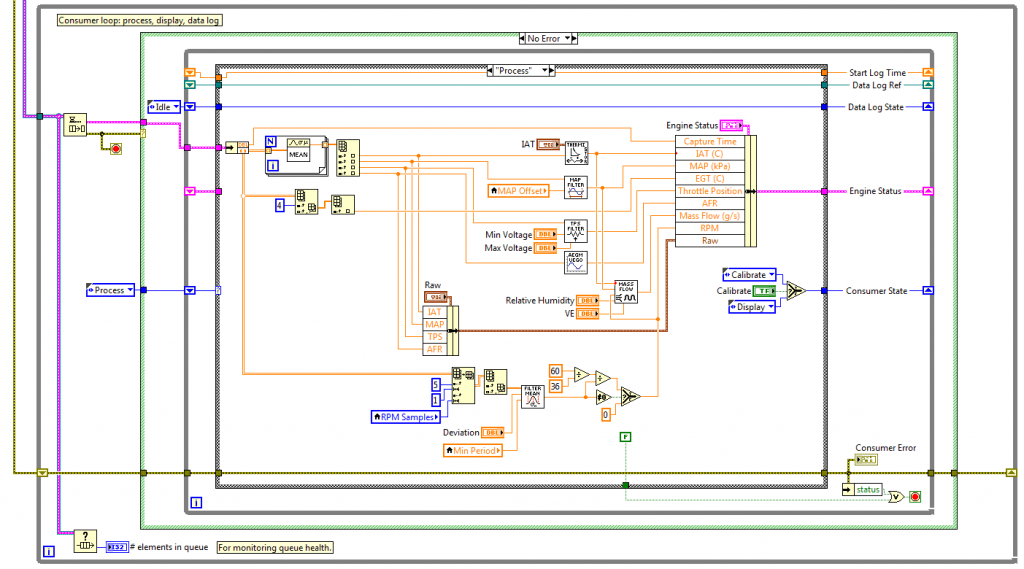

The consumer loop, processing state demonstrating the number of custom VIs developed for the project. These custom VIs simplified the layout and made functionality obvious in addition to adding reusability for other projects.

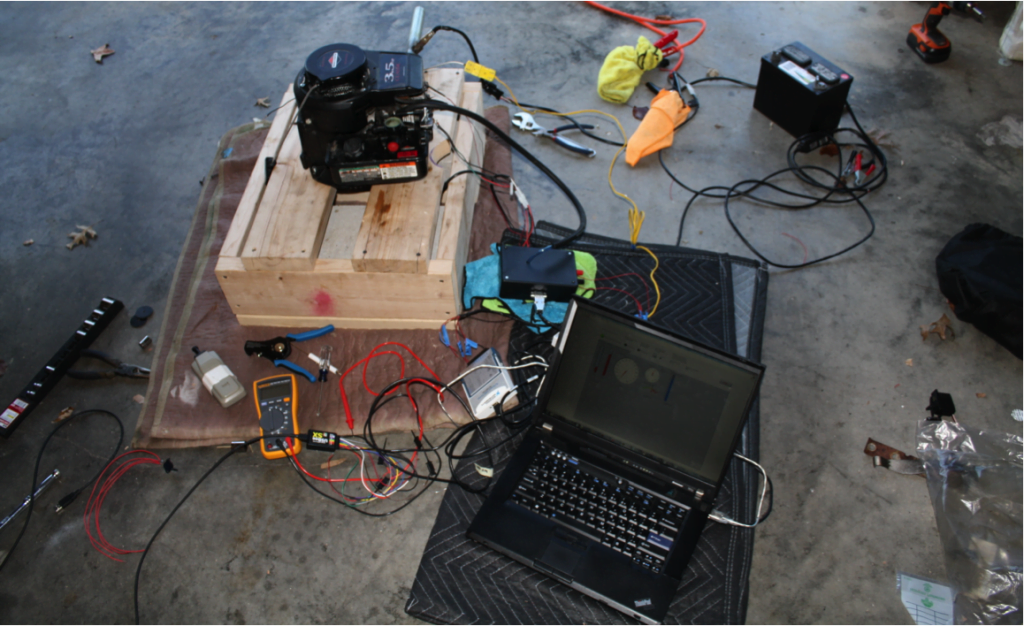

We had access to some more advanced hardware through the Engines Lab and as a result were able to record data at a fairly high throughput. With this data we were able to examine the MAP signal during the intake and calculate true mass flow using the measured value and time differential between samples. If you’re interested in learning more about this project you can download our final presentation from Dropbox. We mounted the engine to a “stand” that we secured with a moving blanket to reduce vibration and to stop it from moving around on the floor. The lawn battery we were originally using for power stopped working so we used my Accord’s battery as power.